If you're planning on building anything with concrete, whether it's a foundation, a driveway, or a slab, you're going to need the right equipment. While there are many tools and machines that can be used for concrete work, some are more essential than others. In this article, we'll go over some of the most important pieces of concrete equipment that you'll need for any building project.

Mixing and Batching Equipment

When it comes to building projects, one of the most important pieces of equipment for any concrete project is a mixer. Whether you're mixing small batches of concrete by hand or using a large, industrial mixer, having the right mixing equipment is crucial to achieving consistent, high-quality results.

Concrete Mixers: Types and functionalities

Concrete mixers come in different types, each with its own functionalities. Here are some of the most common types of concrete mixers:

- Drum mixers: These mixers have a rotating drum that mixes the concrete. They're ideal for small to medium-sized projects and are easy to use.

- Pan mixers: These mixers have a stationary pan and rotating blades that mix the concrete. They're ideal for small to medium-sized projects and are easy to clean.

- Twin-shaft mixers: These mixers have two rotating shafts with mixing blades that move in opposite directions. They're ideal for large-scale projects and can mix high-strength concrete.

- Vertical mixers: These mixers have a vertical axis and use gravity to mix the concrete. They're ideal for small to medium-sized projects and can mix different types of concrete.

Each type of concrete mixer has its own advantages and disadvantages. Depending on your project's requirements, you'll need to choose the right type of mixer.

Formwork and Structural Integrity

Formwork is an essential component of any concrete construction project. It provides temporary support to the freshly poured concrete until it hardens and gains strength.

Types of Formwork: Traditional vs. Modern Systems

Traditionally, formwork systems were constructed using timber. Timber formwork is still used today, but modern formwork systems have been developed to provide more efficiency and durability. Modern formwork systems are typically made of steel, aluminium, or plastic. Here are some of the most common types of formwork:

- Steel Formwork: The most common type of modern formwork system. It is durable, reusable, and can be used for a variety of different construction projects. It is also easy to assemble and disassemble, making it an efficient choice for construction projects with tight timelines.

- Aluminium Formwork: Another popular modern formwork system. It is lightweight, easy to handle, and can be reused multiple times. It is also resistant to corrosion, making it a good choice for construction projects in coastal areas.

- Plastic Formwork: A relatively new formwork system that is gaining popularity due to its versatility and durability. It is made of lightweight plastic panels that are easy to handle and can be reused multiple times. Plastic formwork is also resistant to water and chemicals, making it a good choice for construction projects that involve harsh environments.

Importance of Proper Formwork for Structural Integrity

Proper formwork is essential for the structural integrity of any concrete construction project. Formwork that is not installed correctly can result in structural defects, such as cracks or uneven surfaces. This can compromise the safety and stability of the structure.

In addition to ensuring the safety of the structure, proper formwork can also save time and money. A well-designed formwork system can reduce the amount of time needed for construction and minimize the amount of material waste. It can also improve the quality of the finished product, resulting in a more aesthetically pleasing and durable structure.

Concrete Placement Tools

When it comes to concrete placement, having the right tools can make all the difference. Here are two essential tools for efficient and effective concrete placement:

Concrete Pumps: Pumping Methods and Advantages

Concrete pumps are machines used to transfer liquid concrete from the mixer truck to the construction site. They come in various sizes and types, but the most common types are boom pumps and line pumps.

- Boom Pumps: Have a long arm that can be extended up to 70 meters. They are ideal for high-rise building projects or when the construction site is difficult to access.

- Line Pumps: on the other hand, are smaller and more versatile. They are suitable for smaller construction projects or when the construction site is easier to access.

Material Distribution: Conveyors and Chutes

Conveyors and chutes are also important tools for efficient material distribution during concrete placement. They are used to move concrete from the mixer truck to the desired location on the construction site.

Conveyors are machines that use belts or chains to move material from one place to another. They are ideal for long-distance material transport or when the construction site is difficult to access. Chutes, on the other hand, are simple and effective tools that use gravity to move material from a higher point to a lower point. They are suitable for shorter distances or when the construction site is easier to access.

Surface Preparation Machinery

When it comes to concrete surface preparation, having the right machinery is crucial to achieving a smooth and even finish. Here are two essential types of equipment you should consider for your building project:

Concrete Grinders and Polishers

Concrete grinders and polishers are versatile machines that can be used for a variety of surface preparation tasks. They are capable of removing old coatings, smoothing rough surfaces, and polishing concrete to a high shine. With the right attachments, they can even be used for edge work and to reach tight spaces.

Shot Blasting Equipment

Shot blasting equipment is used to create a profile on the surface of the concrete, which helps coatings and overlays adhere better. This equipment works by propelling small steel balls at high speeds onto the surface, which removes any contaminants and creates a textured surface.

Curing and Moisture Control Equipment

Proper curing of concrete is essential for achieving optimal strength and durability. By using the right equipment, you can ensure that your concrete project will have the strength and durability needed to withstand the test of time.

Importance of Proper Curing for Concrete Strength

Proper curing of concrete is essential for achieving optimal strength and durability. Curing refers to the process of maintaining adequate moisture and temperature conditions for concrete to fully hydrate and gain strength. Curing is critical during the early stages of concrete hardening, as it can significantly affect the final strength and durability of the concrete. Curing time can vary depending on the type of concrete and the environmental conditions.

Curing Blankets, Sprayers, and Moisture Control Systems

To ensure proper curing, various equipment is available to control moisture and temperature conditions. Here are some of the most common types of curing equipment:

- Curing Blankets: Cover freshly poured concrete and prevent moisture loss due to evaporation. They are available in various sizes and materials, including polyethylene, burlap, and cotton. Curing blankets can be reused and are easy to handle and store.

- Sprayers: A popular method for curing concrete. They are used to apply a fine mist of water to the surface of the concrete, which helps to maintain moisture levels and prevent cracking. Sprayers are available in various sizes and can be operated manually or with a motorized pump.

- Moisture Control Systems: Used to regulate the moisture content of concrete during the curing process. They are available in various forms, including moisture curing rooms, concrete curing tanks, and vapor curing systems. These systems maintain a controlled environment of temperature and humidity to ensure proper curing and achieve optimal strength and durability.

Finishing Tools and Equipment

When it comes to finishing a concrete project, having the right tools and equipment is essential. Here are two most important finishing tools and equipment you'll need.

Trowels and Screeds

Trowels and screeds are essential tools for achieving a level surface on your concrete project. A trowel is a handheld tool that is used to smooth and level the surface of freshly poured concrete. A screed, on the other hand, is a long, straight board that is used to level the concrete before it sets.

There are several types of trowels and screeds available, including:

- Finishing Trowels: These trowels are used to achieve a smooth finish on the concrete surface.

- Edging Trowels: These trowels are used to create a clean edge along the concrete surface.

- Bull Floats: These large, flat tools are used to level the concrete surface before finishing with a trowel.

Edgers, Groovers, and Brushes

If you're looking to add texture to your concrete project, edgers, groovers, and brushes are essential tools. Edgers are used to create a rounded edge on the concrete surface, while groovers are used to create a straight line or groove in the surface.

There are also a variety of brushes that can be used to add texture to the surface of the concrete. Some common types of brushes include:

- Broom Brushes: These brushes are used to create a rough, textured finish on the surface of the concrete.

- Stiff-Bristle Brushes: These brushes are used to create a more pronounced texture on the surface of the concrete.

- Soft-Bristle Brushes: These brushes are used to create a more subtle texture on the surface of the concrete.

Testing and Quality Control Devices

When it comes to building projects, ensuring the quality of the concrete used is essential. This is where testing and quality control devices come in. These devices help assess the integrity of the concrete and ensure that it meets the necessary standards.

Concrete Testing Equipment

Concrete testing equipment is used to measure the strength and consistency of concrete. The most common types of tests include compression tests, slump tests, and air content tests.

- Compression Tests: Measure the strength of the concrete by applying pressure to a concrete cylinder until it fails. This test is essential for ensuring that the concrete can withstand the required loads.

- Slump Tests: Measure the consistency of the concrete by measuring the slump of the concrete when it is poured into a mold. This test is essential for ensuring that the concrete is workable and can be placed and finished properly.

- Air content Tests: Measure the amount of air in the concrete. This test is essential for ensuring that the concrete is durable and can resist freeze-thaw cycles.

Non-Destructive Testing Methods

These non-destructive testing methods are essential for assessing the quality of the concrete without damaging it. They are particularly useful for assessing the integrity of existing concrete structures. These methods include:

- Ultrasonic testing: This method uses high-frequency sound waves to measure the thickness and strength of the concrete.

- Ground-penetrating radar: This method uses electromagnetic waves to detect voids, cracks, and other defects in the concrete.

- Rebound hammer: This method uses a spring-loaded hammer to measure the hardness of the concrete.

Safety Gear and Personal Protective Equipment (PPE)

When working with concrete, safety gear and personal protective equipment (PPE) are crucial to ensure the safety of workers. The following table outlines some of the essential safety equipment required for working with concrete:

| Safety Equipment | Purpose |

| Hard hats | Protect the head from falling debris |

| Safety glasses or goggles | Protect the eyes from dust and debris |

| Respirators | Protect the lungs from dust and other airborne particles |

| Earplugs or earmuffs | Protect the ears from loud noise |

| Gloves | Protect the hands from chemicals and other hazards |

| Steel-toed boots | Protect the feet from falling objects or other hazards |

Ensuring worker safety and compliance with regulations

Employers have a responsibility to ensure that workers are provided with the necessary safety gear and PPE when working with concrete. In addition, workers must be trained on how to properly use and maintain their safety gear and PPE. It is also important to ensure compliance with regulations such as those set by Safe Work Australia.

These regulations outline specific requirements for safety gear and PPE when working with concrete. By providing the necessary safety gear and PPE, training workers on their proper use, and ensuring compliance with regulations, you can help ensure the safety of workers when working with concrete.

Innovations and Trends in Concrete Equipment

Concrete equipment has come a long way in recent years, with new innovations and trends emerging to improve the efficiency, quality, and sustainability of concrete production. Here are two trends that are shaping the future of concrete equipment:

Automation and Smart Technologies in Concrete Production

Automation and smart technologies are transforming the concrete production process, making it faster, safer, and more accurate. Automated systems can control the mixing, pouring, and curing of concrete, reducing the need for manual labour and minimizing the risk of errors.

Smart technologies, such as sensors and monitoring systems, can provide real-time data on concrete quality, strength, and durability, allowing for better decision-making and optimisation of the production process. These technologies can also help detect and prevent potential problems, such as cracks or defects, before they become serious issues.

One example of smart technology in concrete production is the use of self-consolidating concrete (SCC), which can flow into complex shapes and tight spaces without the need for vibration or compaction. SCC can be produced using automated mixing and pouring systems, which can reduce labor costs and improve consistency and quality.

Sustainable Equipment Options

Sustainability is becoming an increasingly important consideration in the construction industry, and concrete equipment manufacturers are responding with new eco-friendly options. Sustainable concrete equipment options can help reduce energy consumption, waste, and carbon emissions, while also improving the durability and performance of concrete.

One example of sustainable concrete equipment is the use of electric-powered mixers and pumps, which can reduce fuel consumption and emissions compared to traditional diesel-powered equipment. Another example is the use of recycled aggregates and supplementary cementitious materials, such as fly ash or slag, which can reduce the need for new materials and lower the carbon footprint of concrete.

In addition, some manufacturers are exploring the use of renewable energy sources, such as solar or wind power, to power concrete production equipment. These sustainable options can help reduce the environmental impact of concrete production while also improving the bottom line for contractors and builders.

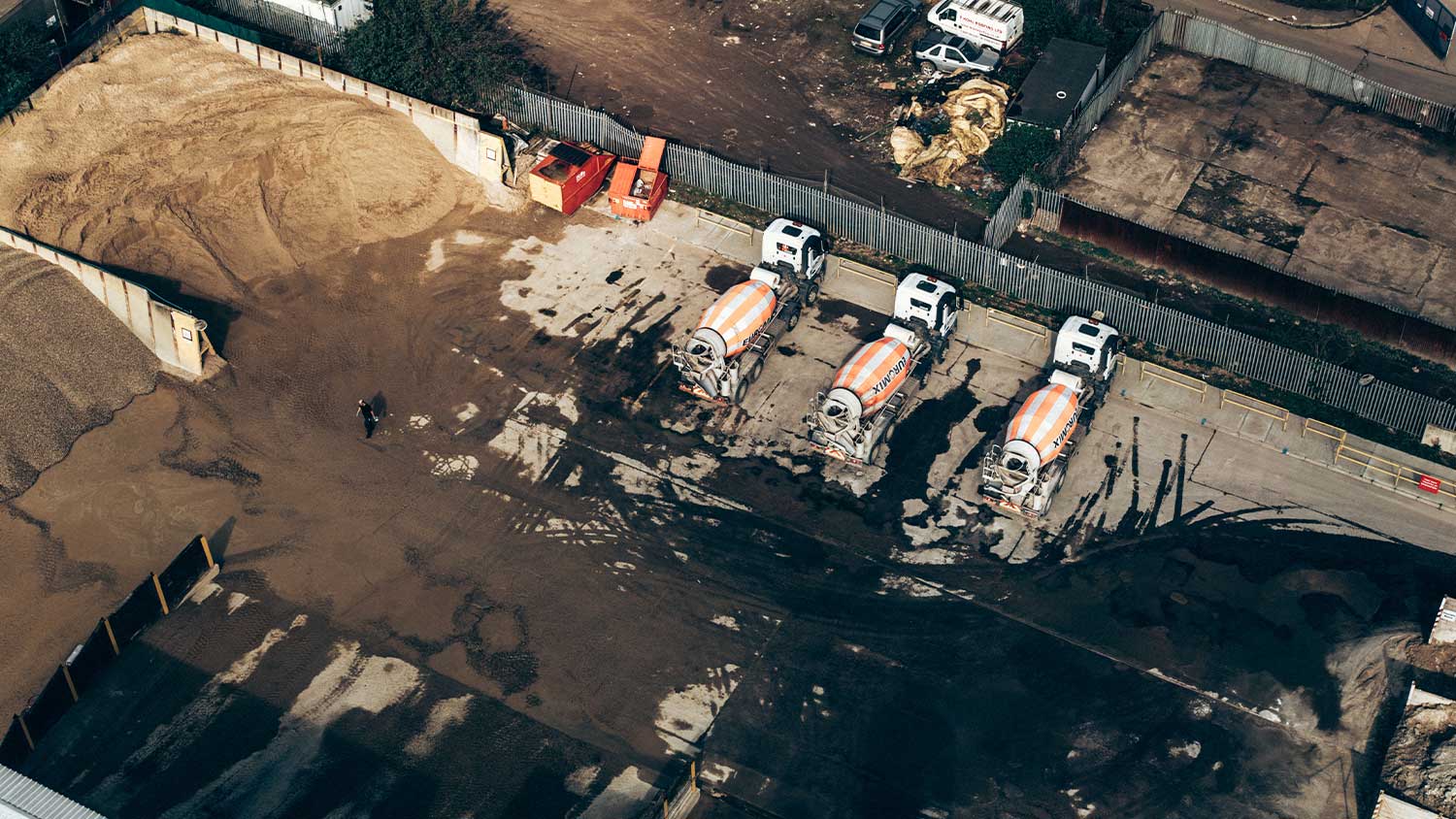

Cleanup and Washdown of Concrete Equipment

Proper cleanup of concrete equipment are essential to ensure that they function effectively and efficiently throughout their lifespan. Neglecting cleaning can lead to equipment breakdowns, costly repairs, and even accidents. After each use, the equipment should be cleaned thoroughly to remove any concrete residue, dirt, or debris. Use a pressure washer or a hose to clean the equipment, and avoid using abrasive materials that can damage the surface of the equipment.

SLURRYTUB The Environmental Solution

When it comes to cleaning it is essential to be aware of the environmental impact of waste usage but also mindful of the dirty contaminates you are washing onto the ground. SLURRYTUB is a portable filtering system that provides a simple and cost-effective environmental solution for the disposal of wet trade slurry. The system is designed to filter out solids and contaminants from wet trade slurry, allowing for safe and easy disposal. The system is also environmentally friendly, as it reduces the amount of waste that goes into landfills, making it an excellent addition to any construction site.

Wrap Up

Having the right concrete equipment is crucial for any building project. It ensures that the job is done efficiently and effectively, saving time and money in the long run.

Investing in high-quality equipment is a wise decision as it lasts longer and performs better than cheaper alternatives. It is also important to ensure that the equipment is well-maintained and regularly serviced to prevent breakdowns and ensure safety on the job site.

Some of the essential equipment for concrete construction projects includes mixers, pumps, trowels, and saws. Each of these tools plays a vital role in the construction process and can help achieve a smooth and even finish.

It is also important to have the right safety equipment, such as gloves, safety glasses, and hard hats, to protect workers from injury. Additionally, having a reliable tracking system for equipment can help prevent loss and theft, ensuring that the project stays on track.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.