Managing concrete disposal is an important aspect of any construction project. It is crucial to have a waste management plan in place to ensure that concrete waste is disposed of in an environmentally friendly manner. This not only helps to reduce the impact on the environment but also ensures compliance with regulations and guidelines. In this article, we will discuss best practices and environment-friendly options for managing concrete disposal.

Understanding Concrete Slurry Disposal

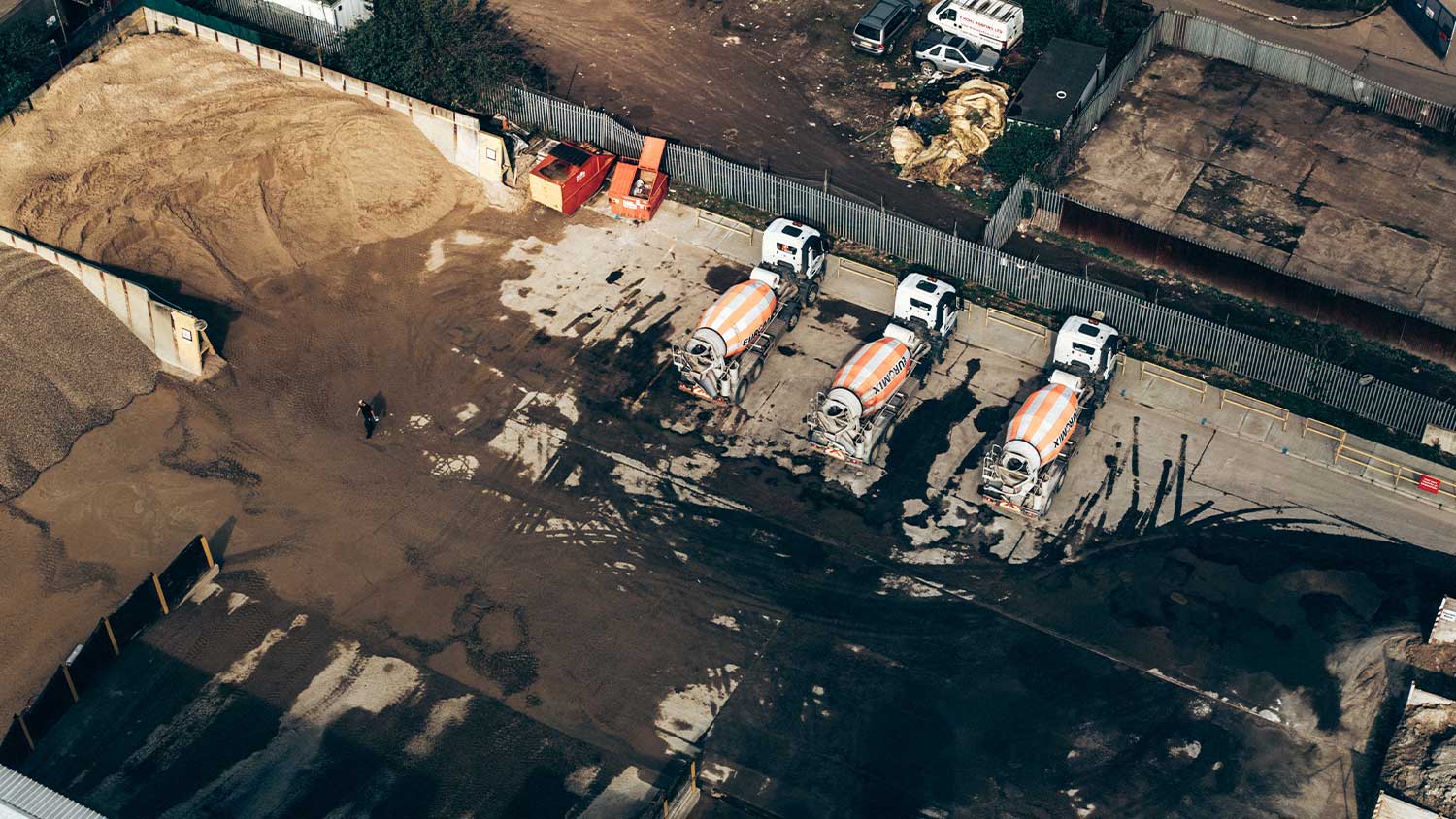

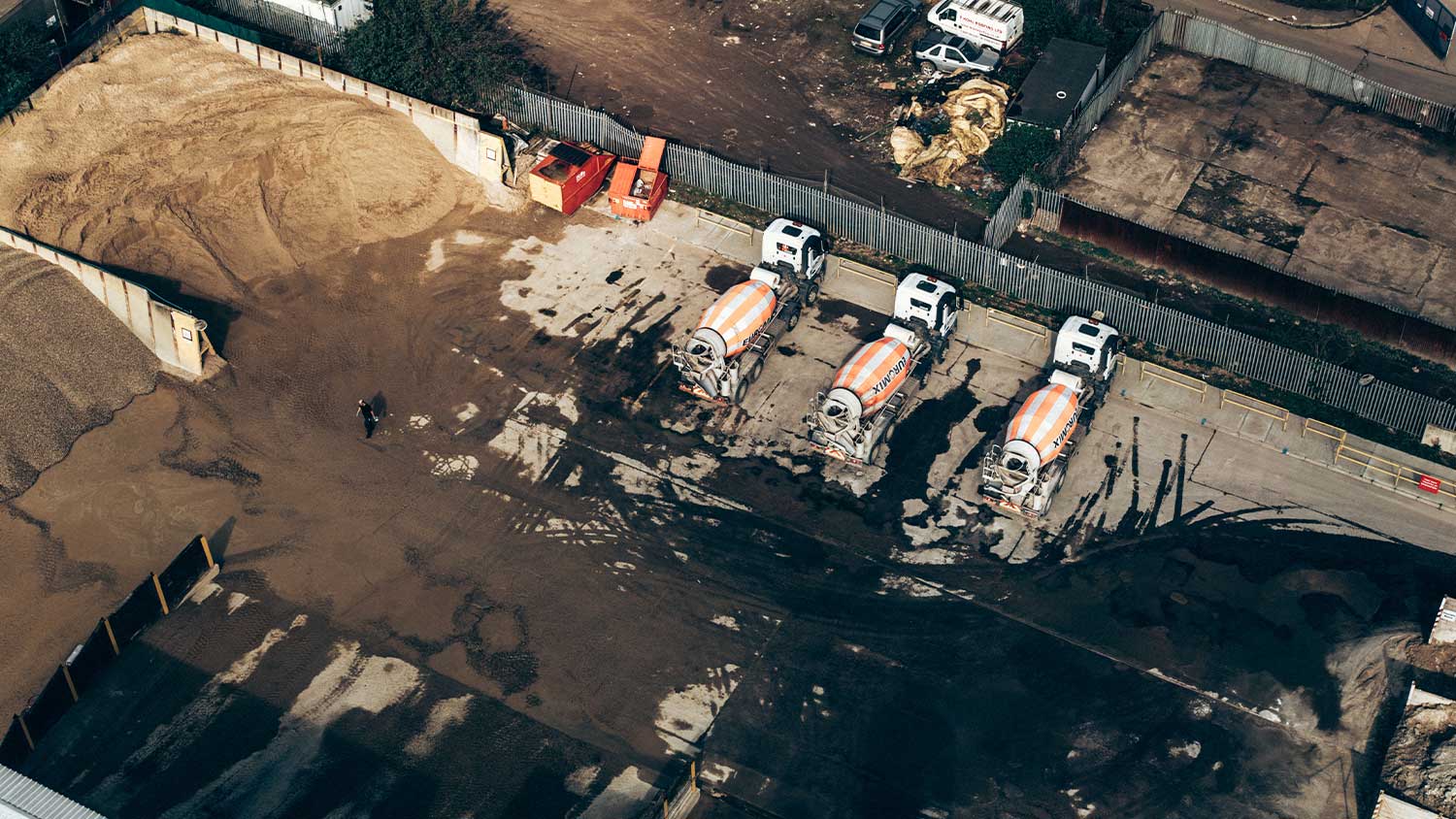

When working with concrete, one of the challenges is dealing with the byproduct known as slurry. Slurry waste is generated when water and cement are combined during the concrete mixing process. Concrete slurry waste contains cement, sand, and other nasty chemicals. Wet trade slurry is classified as hazardous waste due to its high pH level and total suspended solids.

This leaves a tricky problem for builders to solve when it cannot be disposed of in the same way as regular construction waste. Therefore, it is crucial to have effective wet trade management strategies in place to manage concrete slurry waste.

Environmental Impacts of Concrete Slurry Disposal

Disposing of concrete can have significant environmental impacts if not carried out properly. Concrete is a heavy and dense material that can take up a lot of space in landfills. When concrete is disposed of in landfills, it can take hundreds of years to decompose, and the chemicals in the mix can leach into the soil and groundwater, causing pollution. Additionally, the transportation of concrete to landfills can contribute to air pollution and global warming.

Wastewater is another environmental concern when it comes to concrete disposal. When concrete is washed off trucks and equipment, the wastewater contains chemicals and cement particles that can harm aquatic life and pollute waterways.

Concrete Slurry Disposal Best Practice

To minimise the environmental impacts of concrete disposal, it is important to consider alternative options. This best practice solution can significantly reduce the amount of waste sent to landfills and stop chemicals from washing down the stormwater.

Firstly, every construction project must have a designated washout area. This area should be lined with a barrier to prevent contamination of the soil and groundwater. Commonly slurry will be disposed of here and then is allowed to dry out and solidify. However, ending the process here means a costly clean-out at the end of any construction project.

The next step and the most effective solution for concrete slurry disposal is to filter and recycle it. Recycling concrete slurry waste within your designated washout area can help reduce waste and recycle water. The process involves filtering the water from the solid waste, then using the leftover water for other purposes, such as cleaning equipment or new mixes. The separated solid remains have now been significantly reduced and can be used and disposed of properly, saving time and money.

Your slurry management plan should also address containment of slurry leaks and spills, it is also important to note that concrete slurry is prohibited from being dumped straight down the drain as it can cause blockages and harm to aquatic life. By implementing a wet trade management strategy, you can help reduce the impact on the environment and ensure compliance with regulations and guidelines.

Filtering and Recycling

When it comes to concrete disposal, water is an essential component that is often overlooked. Wet trade water waste, which includes water used for mixing, washdown, washup, and cutting concrete, can be a significant problem as it builds up on site. Fortunately, there are a couple of techniques that help reduce water usage and minimise its environmental impact.

One of the most common ways to recycle wet trade water waste on big construction sites is through a process called settling. This involves allowing the water to sit in a tank or basin until the sediment and solids settle to the bottom. The clean water can then be reused for mixing or washing, while the sediment can be disposed of separately.

Another option that is great for any construction site is to use a filtration system to remove impurities from the water. The wet trade waste is poured into a filtration system which captures all the leftover aggregates and nasty chemicals. The filtered water can then be reused for mixing or washing, or even for irrigation or other non-potable purposes. Using a filtration system is perfect for daily cleaning and keeping on top of your water waste.

Cost and Economic Implications

Managing concrete disposal can have significant cost and economic implications. Poor practices can lead to fines and other financial penalties from local councils. Additionally, improper disposal can hurt stormwater, soil, and groundwater, leading to further environmental and economic consequences.

When concrete waste is not responsibly managed, it can have a significant impact on the environment. Improper disposal can lead to soil and groundwater contamination, which can be costly to remediate. In addition, improperly disposed of concrete waste can block stormwater systems, leading to flooding and other costly damages.

On the other hand, recycling concrete waste can have significant economic benefits. By recycling concrete waste, businesses can reduce the amount of waste they send to landfills, which can result in cost savings. In addition, recycled concrete can be used as a substitute for natural aggregates, reducing the need for costly extraction and transportation of these materials.

A comparative study of the costs and benefits between the current practice and the concrete recycling method is shown in this paper. The study shows that recycling concrete waste can be a cost-effective solution for managing concrete waste.

How to Start Managing Concrete Slurry Disposal?

SLURRYTUB is a portable filtering system that provides a simple and cost-effective environmental solution for the disposal of wet trade slurry. It is the market's only solution to a growing waste problem in the construction industry.

SLURRYTUB’s 'best practice' solution was designed to significantly improve the environmental performance of construction sites by eliminating any suspended solids from entering the watercourse and saving and recycling water.

The SLURRYTUB solution is a vast improvement on current practices and makes it easier to meet all council guidelines. We recognize that regulators and councils cannot specifically endorse SLURRYTUB as a product, however, we are of the view that the current guidelines are outdated and should be revised. We recommend that the current guidelines be updated to incorporate the following:

- All slurry should be retained in a waterproof vessel before hitting the ground

- Any filtering of the slurry should occur before being placed in the vessel, or in the vessel itself, and not after it has hit the ground as this is too late

- The separated slurry should be deposited in a skip or other appropriate waste disposal system

- Any filtered water should be recycled on the job (creating a closed loop), or appropriately disposed of offsite, allowing nothing but rainwater to go down the stormwater

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.